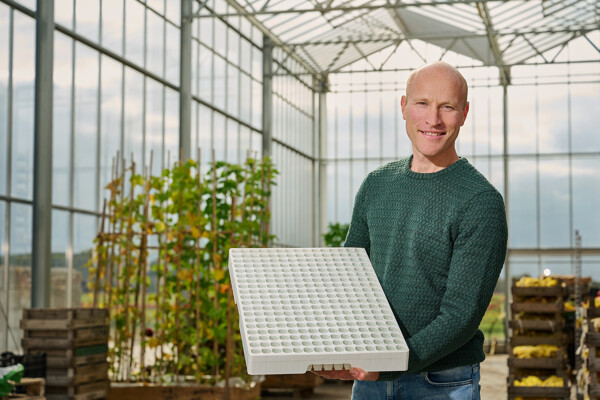

Nursery Fa. Bisschops

'At Fa. Bisschops we grow Dahlia bulbs, among other things. And we have been doing so with great care and attention for generations.

Why Growcoon? That needs an introduction...

'Our Dahlia bulbs are exported mainly to America. And therefore they need to be well rinsed. When you grow for example in potting soil, sometimes peat remains on the tuber. But that's not allowed. The authorities are very strict about that.'

100% biodegradable

Natural microclimate

Unique fit

Choose your own substrate

'Because we grow in poor, cold soil, the Progressive Growcoon is sometimes not fully degraded at the time the tuber is harvested. The authorities were somewhat skeptical about that in America. But recently the NVWA approved the use of the Growcoon. Thanks to the efforts of advocate Anthos. A milestone for us! Now we can scale up!'

'So we grow up our Dahlia cuttings in poor soil, because that attaches much less to the tuber/root. We still do this most often in open cutting trays, but this causes damage during transplanting. Which unfortunately leads to some failure. This is why we have been investigating for some time whether we could make the switch to plug trays. But loose sand in a plug tray doesn't work... However, it does in combination with a Growcoon! And this offers another big advantage. Namely that the planting process can be automated. In view of rising labor costs, that is perhaps the biggest gain!'

A family business for 3 generations

'Brothers Mark and Eric Bisschops are in charge of the nursery. Their grandfather, Leo Bisschops, is the founder of it. Dahlias run like a silver thread through the company's history. 'We have the entire cultivation process, from propagation to marketing, in-house.'

The cultivation cycle from cutting to tuber takes less than a year. 'In February we start with cuttings. In total we produce about 3 million. Before July we want to have these planted out in the open field. Eventually we harvest about 135,000 tubers per hectare. 10 to 20 percent of the total number of cuttings are falling out now. We would like to reduce that number. In the cutting phase we make the most costs. So you want to get as much return from that as possible. Growcoon not only binds the root ball, but also has everything we need to drastically reduce the failure rate in this critical phase!'

'Transplanting requires quite a bit of manual labor. So high labor costs. Automation would bring huge benefits. Hopefully one that we can realize in the near future (perhaps in cooperation with other growers). Through Growcoon, it will become possible.'

Growcoon & Automation

For many growers, automation is the way to smoothly scale up and reduce labor costs. Growcoon makes automation possible. With a Growcoon Dispenser, the Growcoon is automatically placed in the tray. In addition, a Growcoon makes automated transplanting of a cutting easier. During the process, the root ball remains intact and the root system is protected. This makes it even possible to transplant at an earlier stage.

Growcoon & Biodegradability

The Growcoon is produced entirely of biodegradable materials. It degrades slowly from the moment it comes into contact with microorganisms in a substrate. In the end, nothing is left but water and CO2. And that is why the Growcoon is approved in Europe for organic cultivation. Growcoon is SKAL certified and is also on the Ecocert list for organic farming. Growcoon leaves no toxic residues and waste. Very healthy and zero waste!